Key points from article :

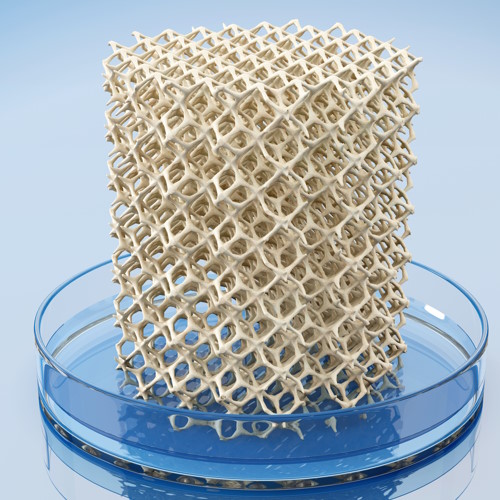

New technology can very quickly print large numbers of custom tissue samples that are suitable for drug screenings.

“With human tissues, you can get better data – real human data – on how a drug will work,” said Shaochen Chen, on of the researchers.

“Our technology can create these tissues with high-throughput capability, high reproducibility, and high precision."

"This could really help the pharmaceutical industry quickly identify and focus on the most promising drugs.”

“When you’re scaling this up to a 96-well plate, you’re talking about a world of difference in time savings."

"At least 96 hours using a traditional method plus sample transfer time, versus around 30 minutes total with our technology.”

The researchers can use medical scans to create custom samples that are individual to specific patients.

The computer model is then divided into two-dimensional slices and the printing occurs slice-by-slice.

An array of mirrors and a light-sensitive polymer help the system to rapidly create a 3D polymer structure containing live cells.

"...With a pencil, you’d have to draw every single line until you complete the shape. But with a stamp, you mark that entire shape all at once. " - Henry Hwang, another of the researchers.

"That’s what the digital micromirror device does in our technology. It’s orders of magnitude difference in speed."

A study carried out by UCSD, California published in Biofabrication.