Key points from article :

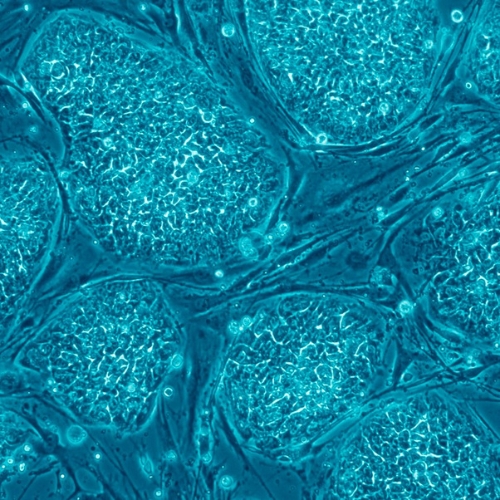

Induced pluripotent stem (iPS) cells can morph into good replacements for other cells.

“What makes cells so great is what makes them difficult to manufacture,” - Bollenbach, chief technology officer at ARMI.

Stem cell-based therapies must conquer 2 manufacturing challenges: automated production and volume.

Firms were launched to provide mass production and differentiation of iPS cells.

TreeFrog Therapeutics announced production of a single batch of 15 billion iPS cells in a week.

Cellino Biotech offers a platform for fabricating autologous iPS cell therapies.

“Target manufacturing cost for 2025 is $30,000/dose,” - Nabiha Saklayen, CEO of Cellino Biotech.

Kytopen developed a microfluidic platform to create iPS cells and other forms of cell therapy.

Its system can transfect hundreds of millions of cells in a minute, at the push of a button.

“There are still obstacles to obtain regulatory approval, ” - Kapil Bharti, a molecular-cell biologist at NIH.

All these problems will be overcome, advocates say.