Key points from article :

Bone is a mixture of living and inorganic compounds in a highly structured mineral matrix.

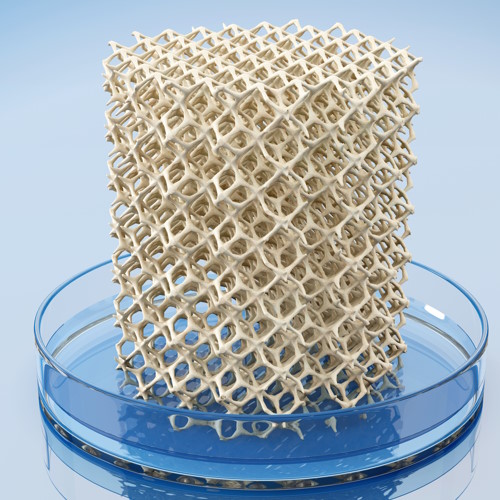

3D printing bone is a challenge within a challenge.

Bioengineers developed a ceramic ink that can be 3D-printed at room temperature with live cells.

Eventually, be used to print bone directly into a patient’s body.

“....print constructs in situ which mimic the structure and chemistry of the bone,” study co-author Iman Roohani.

A biocompatible calcium phosphate material forms a paste at room temperature.

Paste hardens into a porous nanocrystal matrix similar to native bone tissue.

Equipped an off-the-shelf 3D printer, the Hyrel 3D Engine HR, with a custom nozzle.

Can be adapted to portable and handheld printers to be taken into a surgical room.

Cells adhered and proliferated for several weeks after printing with 95% viability.

3D-printed bone technologies are eligible for FDA clearance.

Research by University of New South Wales published in the journal Advanced Functional Materials.