Key points from article :

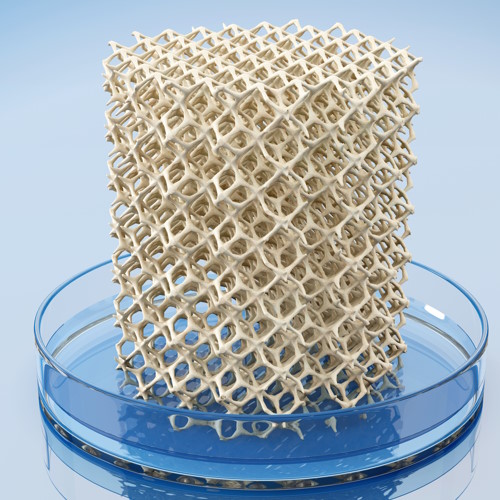

Researchers developed a new 3D printing technique creating incredibly small and complex biomedical implants.

Involving glue printing molds that can then be filled with biomaterial filler.

Researchers realized that printing an inverse shape might be a better approach for complex structures.

Cathal O’Connell, a researcher involved in the study said

"The shapes you can make with a standard 3D printer are constrained by the size of the printing nozzle ..."

This technique is called as Negative Embodied Sacrificial Template 3D (NEST3D) printing.

The printed PVA structures can be dissolved from biomaterial core by placing them in water.

Researchers are able to produce 3D structures that can be just 200 microns across.

Which rivals the achievability by light-based fabrication techniques.

Research by RMIT University published in Advanced Materials Technologies.