Key points from article :

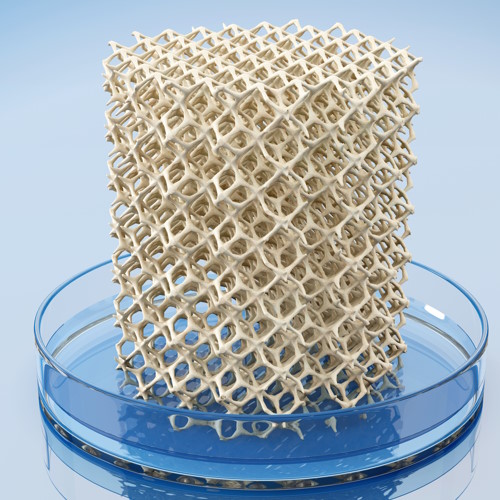

The 3D printing of medicine in highly porous structures can regulate the rate of drug release when taken orally.

“New technology produce pills that have accurate dose and drug combinations tailored to individual patients," - Sheng Qi, Research leader.

"This would allow the patients to get maximal drug benefit with minimal side effects," - Qi.

Pharmaceutical 3D printing research has rapidly developed in the past five years.

Most commonly methods require the drug being processed into filaments prior to 3D printing.

New 3D printing method, hot melt droplet deposition, can rapidly produce porous pharmaceutical tablets without the use of filaments.

By changing the size of the pores, the speed of a drug escaping from the tablet into the body can be regulated.

This principle to build multiple medicines into a single poly-pill for patients who are on a complex medicine regimen.

Research by UEA and Loughborough University published in International Journal of Pharmaceutics.