Key points from article :

A team led by Changhong Cao at McGill University has developed a novel approach to ultra-fine 3D printing by repurposing the proboscis of the female Aedes aegypti mosquito as a high-precision nozzle. The work, described as “3D necroprinting,” was driven by the need for extremely narrow and affordable nozzles to print delicate biological structures. Commercial options offered a minimum bore of 35 micrometres and came with high costs, while handmade alternatives like glass-pulled nozzles proved fragile and impractical.

Cao’s team discovered that mosquito mouthparts, refined over millions of years of evolution, offer a naturally rigid and incredibly thin channel capable of printing structures as small as 20 micrometres. The nozzles are inexpensive—costing under a dollar each—and can be produced at scale, with an experienced worker able to prepare around six per hour. Despite their biological origin, they remain functional for up to two weeks and can be stored frozen for a year.

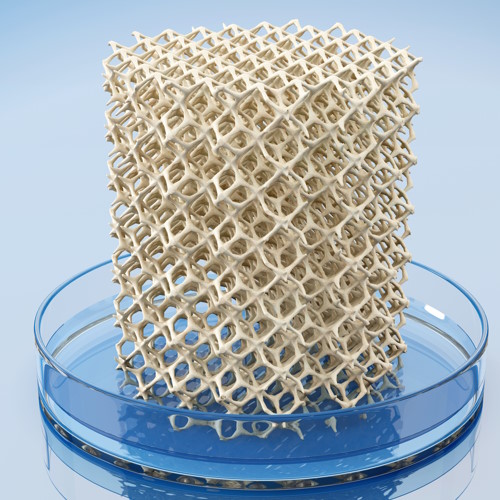

Using these natural nozzles, the researchers successfully printed with Pluronic F-127, a bio-ink used to create scaffolds for tissues such as blood vessels. This proof of concept suggests that nature’s own engineering may help accelerate future organ fabrication technologies. As Christian Griffiths from Swansea University notes, the work highlights how human ingenuity still struggles to match the sophisticated tools shaped by evolution.