Key points from article :

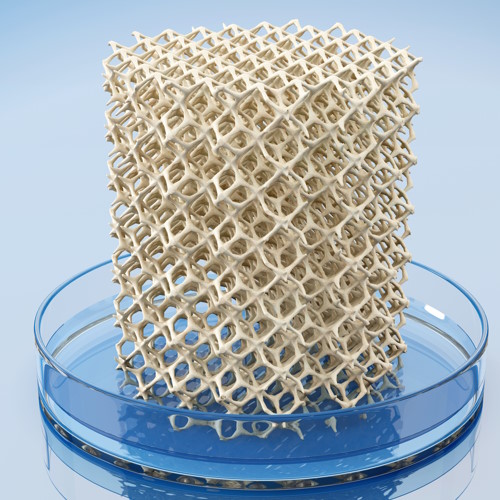

New patent-protected system guarantees print uniformity while printing semi-solid doses with FabRx’s M3DIMAKER STUDIO software.

Uses pressure sensor to analyze printability in-situ under precise printing conditions for three materials.

Enables precise control of materials and process variables for high-fidelity 3D printing, crucial for personalized medicine.

Pressure sensor attached to printhead records flow behavior of semi-solid masses through small nozzles.

Eliminates external equipment by characterizing masses directly on the printing platform for accurate optimization.

Enables mass characterization under actual printing conditions with same equipment and setup, reducing external factors.